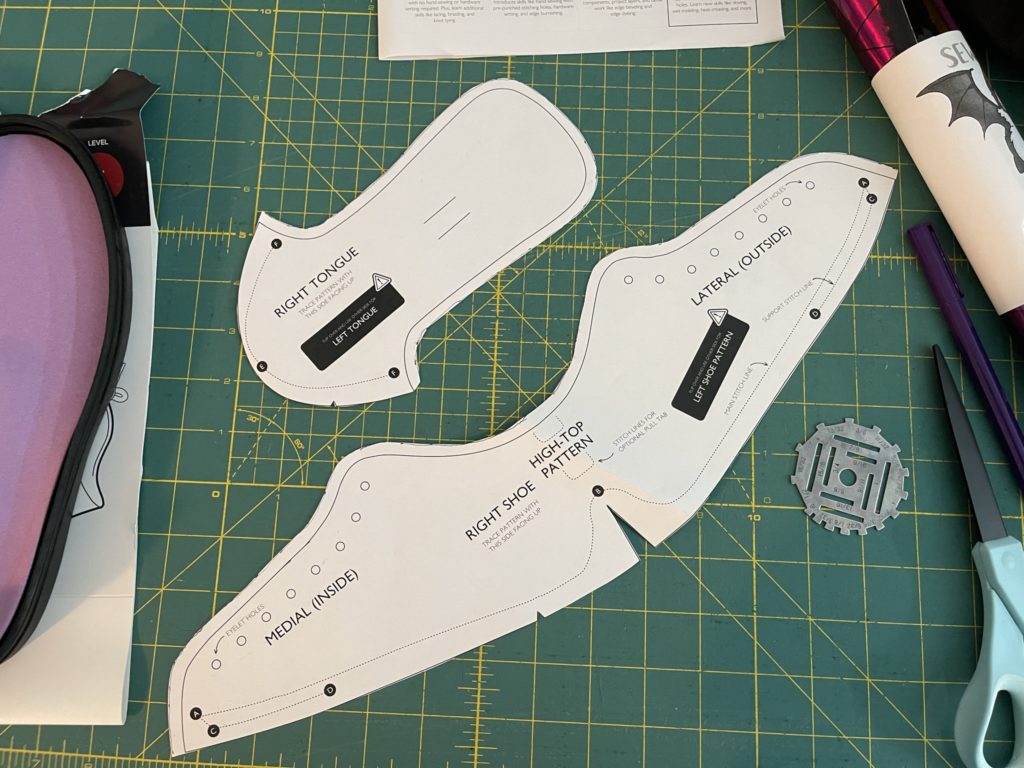

Making custom shoes has been something I’ve wanted to do for a very long time. Shoemaking is an incredible craft that requires a lot of skill and some specialized equipment. But there are now sneaker kits that come with premade and punched soles, insoles, and patterns. I used the kit from Tandy Leather to make my sneakers. Even though the kit is for leatherworking, I modified the process a bit to use vinyl and fabric. Here’s how I did it!

I picked out a vinyl for the exterior of the sneaker, and a quilting-weight cotton for the lining. The main change I made was to add 1/4″ seam allowance to the top of the sneaker sides pattern and the top and sides of the tongue. I did not add seam allowance to the edges of the pattern that would be sewn into the sole.

I cut each piece out of both the vinyl and the lining fabric, then sewed the pieces together along the edges that I added seam allowance to. I turned them right side out through the open sides and topstitched all the way around.

After that, it was a matter of following the directions: adding the eyelets and sewing the pieces to the sole (by hand, using waxed thread, a sewing awl, and a needle). It was a bit tough at one point because the pattern does account for a small amount of stretch in the leather, which vinyl does not have at all. When I make more, I may add a bit of length to the shoe sides to account for this. But I think they still came out great!

Have you ever made your own shoes?

What wonderful shoes! Do you think a waxed canvas would work instead of the vinyl? Would interfacing be needed? I really want to try this!

I bet a waxed canvas would work great!! No interfacing needed. I would love to see them when you make them!